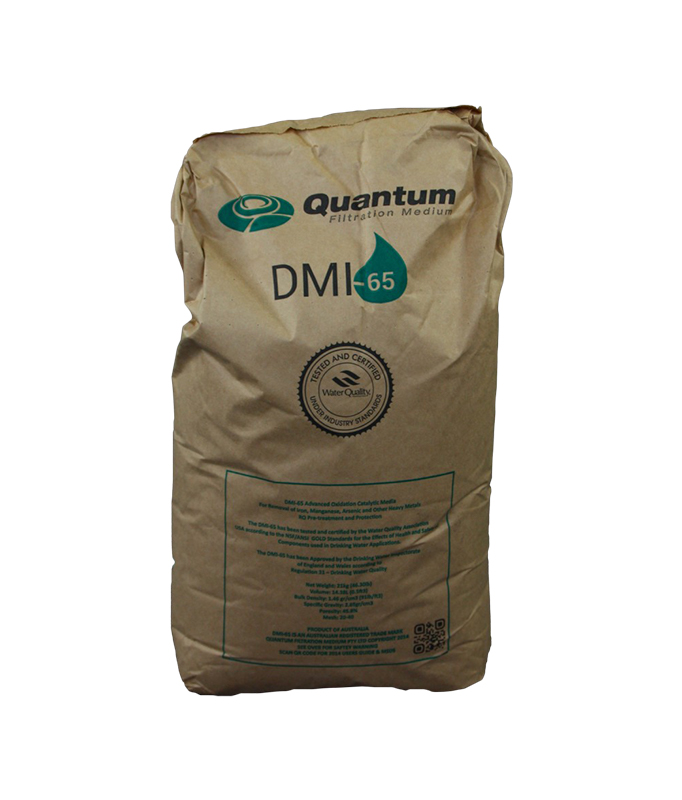

DMI 65 Media 21Kg

DMI–65 Media is a revolutionary Advanced Oxidation Catalytic Filtration Media designed for the removal of iron and manganese. DMI–65 Infusion Technology increases the micro-porous catalytic surface area, efficiently removing more dissolved iron and manganese to as low 0.001 ppm.

It is an extremely powerful catalytic water filtration media that is designed for the removal of iron and manganese in aqueous solutions (water) without the need for potassium permanganate or chemical regeneration. The unique microporous structure of DMI-65 efficiently removes dissolved iron to the almost undetectable levels as low as 0.001 ppm and manganese to 0.001 ppm. DMI-65 acts as an oxidation catalyst with immediate oxidation and filtration of the insoluble precipitates derived from this oxidation reaction. DMI-65 can also remove Arsenic, Aluminium and other heavy metals and Hydrogen Sulphide under certain conditions.

OXIDATION BOOSTER Catalytic Surface is the strongest oxidizing booster that is the most efficient material in the world to remove Mn to undetectable levels. The characteristics of DMI 65 filter media are such that the DMI 65 is easy to use and provides flexibility when upgrading old water treatment systems.

Safe and clean drinking water is a basic human right, however many water sources are currently not viable without a new approach to industrial-grade water filtration.

DMI-65 is a revolutionary Advanced Oxidation Catalytic Filtration Media designed to remove iron and manganese.

It has a unique long life span of up to 5 – 10 years, unlike other water filtration products. This results in significant advantages such as lower costs, higher performance, and less maintenance.

Most industries that use water in their production require water purification to ensure the integrity of their products, the highest quality output, and increased performance of their processing and manufacturing equipment.

We are proud to have served a diverse range of clients for over 20 years in more than 65 countries and have partnered with numerous companies and large enterprises for joint ventures. Some of the biggest clients for DMI-65 include municipal governments, state-owned enterprises, and world aid organizations.

The application of DMI-65 spans a diverse group of industries, both the public and private sectors for small business and industrial applications.

DMI is produced in Western Australian with Quantum Filtration and exported around the world.

ADVANTAGES OF DMI-65 Media

- Eliminates Potassium Permanganate. Operates with continuous injection of sodium hypochlorite at low residual levels (0.1 to 0.3 ppm).

- Wide pH range. Stable and satisfactory performance at pH 5.8 to 8.6.

- High Flow Rates. DMI-65 can operate at linear filtration velocities up to twice that of conventional media with a Higher Operating Temperatures. The maximum operating temperature of 113° F (45° C).

- Long Life. DMI-65 is not consumed in the process

- providing considerable advantages over other processes or media.

- Regeneration Not Required. After initial activation

- only sodium hypochlorite feed is required.

- System Compatibility. Physical properties are similar to that of competitive media

- allowing conversion to DMI-65 without major hardware modifications.

- Arsenic Removal. DMI-65 has been shown to be effective in the removal of arsenic associated with iron-containing influent. If necessary

- ferric chloride can be introduced to treat waters with low influent iron levels or to enhance removal when treating waters with high levels of arsenic.

Reviews

There are no reviews yet.