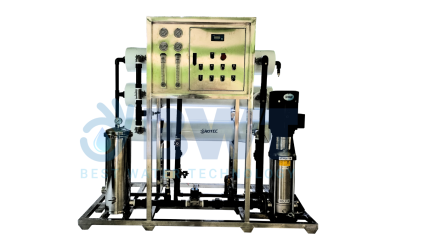

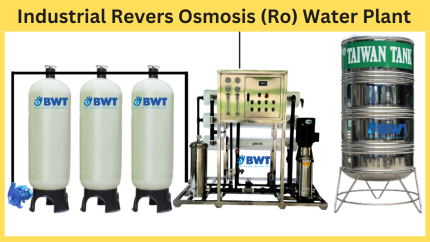

Industrial Iron Treatment Plant in Bangladesh

Iron contamination in water sources poses a significant challenge for industries in Bangladesh. Excess iron not only causes discoloration and foul odor but also damages equipment and reduces operational efficiency. An Industrial Iron Treatment Plant is the ultimate solution for addressing these issues effectively. This guide delves into the importance, working mechanisms, and benefits of iron treatment plants in Bangladesh, highlighting their role in ensuring clean and safe water for industrial use.

Understanding Iron Contamination in Water

Iron contamination is commonly found in groundwater, particularly in regions where geological formations are rich in iron minerals. In Bangladesh, many industries rely on groundwater, making them prone to issues caused by excess iron, including:

- Staining: Iron deposits stain equipment, pipes, and fixtures.

- Clogging: Iron precipitates can clog pipelines and machinery.

- Corrosion: Iron accelerates corrosion, reducing the lifespan of industrial systems.

- Health Risks: High levels of iron can be harmful if used in food processing or other sensitive industries.

Key Features of an Industrial Iron Treatment Plant

Industrial iron treatment plants are designed to remove excess iron from water effectively. Key features include:

- Pre-Filtration Systems: Removes suspended solids and large particles.

- Advanced Filtration Media: Utilizes specialized media like manganese greensand, zeolite, or BIRM for iron removal.

- Oxidation Chambers: Converts dissolved iron into insoluble forms for easier removal.

- Automatic Backwash Systems: Ensures continuous operation and reduces maintenance efforts.

- Customizable Capacity: Plants are available in various sizes, tailored to industrial requirements.

Working Mechanism of Iron Treatment Plants

The typical process of iron removal in industrial plants involves the following steps:

1. Aeration

Air is introduced into the water to oxidize dissolved iron, converting it into ferric iron (solid form).

2. Filtration

The oxidized iron particles are filtered out using advanced filtration media such as manganese greensand or activated carbon.

3. Chemical Treatment

In cases where aeration alone is insufficient, chemicals like chlorine or potassium permanganate are added to enhance oxidation and improve efficiency.

4. Backwashing

The filtration system undergoes regular backwashing to remove trapped iron particles and maintain efficiency.

Benefits of Industrial Iron Treatment Plants

- Enhanced Water Quality: Removes iron and other contaminants, ensuring clean water.

- Protects Equipment: Prevents scaling, clogging, and corrosion in industrial systems.

- Cost-Effective Operations: Reduces maintenance costs and improves the lifespan of machinery.

- Compliance with Standards: Ensures water quality meets industrial and environmental regulations.

- Scalability: Customizable designs to cater to industries of all sizes.

Applications of Industrial Iron Treatment Plants

1. Textile Industry

Iron-free water is essential for dyeing and washing processes to maintain fabric quality.

2. Food and Beverage Industry

Ensures safe water for production, adhering to stringent health standards.

3. Pharmaceutical Industry

Eliminates impurities that could compromise product quality.

4. Power Plants

Prevents scaling and corrosion in boilers and cooling systems.

5. Chemical Manufacturing

Ensures process efficiency and protects sensitive equipment.

Iron Treatment Plant Price in Bangladesh

The cost of an industrial iron treatment plant in Bangladesh depends on factors such as capacity, design, and additional features. On average:

- Small-Scale Plants: BDT 100,000 – 300,000

- Medium-Scale Plants: BDT 500,000 – 1,000,000

- Large-Scale Plants: Above BDT 1,000,000

Investing in a high-quality iron treatment plant from trusted suppliers like BestWaterBD ensures long-term benefits and reliability.

Why Choose BestWaterBD for Industrial Iron Treatment?

- Proven Expertise: Years of experience in providing top-notch water treatment solutions.

- High-Quality Products: Uses advanced technology and durable materials.

- Customizable Solutions: Tailored designs to meet specific industrial needs.

- After-Sales Support: Comprehensive maintenance and support services.

- Competitive Pricing: Offers value-for-money solutions without compromising on quality.

FAQs

1. What is the typical lifespan of an iron treatment plant?

With proper maintenance, an industrial iron treatment plant can last 10-15 years or more.

2. How often should the filtration media be replaced?

Filtration media typically need replacement every 2-5 years, depending on usage and water quality.

3. Can an iron treatment plant handle other contaminants?

Yes, many systems can also remove manganese, hydrogen sulfide, and other impurities.

4. How do I determine the right capacity for my industry?

Capacity depends on your daily water usage and the level of iron contamination. Contact BestWaterBD for a professional assessment.

5. Is regular maintenance required?

Yes, periodic maintenance, including backwashing and media replacement, ensures optimal performance.

Conclusion

An Industrial Iron Treatment Plant is essential for industries in Bangladesh to ensure clean and safe water. From protecting equipment to improving water quality, these plants offer numerous advantages. By choosing a trusted supplier like BestWaterBD, you can invest in a reliable and efficient solution tailored to your needs. Explore the range of iron treatment plants available at BestWaterBD and elevate your water treatment capabilities today.

Reviews

There are no reviews yet.